-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

-

-

View Picture

1936 – Buick Speedster Special in Argentina

Almost three years ago our website received an eMail from Ariel Bassanetti requesting some specification and technical information about a 1936 Buick 8/40 which he was using as the basis of a sports roadster special he was building. Ariel is from Argentina and has a specialist gasket manufacturing business in the outer south-east suburban area of Buenos Aires. It seems that information about early Buicks is scarce in Argentina.

Despite some translation difficulties, as I don’t speak Spanish, since the first eMail there have been several more, many including photos of Ariel’s Buick project and we have followed progress and supplied tit-bits of information as requested, all with great interest. Frank Hall and the club library have provided many of the answers. This is no “hot rod” as, although it is a speedster special, it maintains it’s 1936 Buick mechanicals throughout the car. When one considers the magnitude of the technical and mechanical difficulties Ariel faced with almost all aspects of the build, one must admire the thought and effort he exerted to achieve such an interesting and functional result. Lets hope his work inspires many enthusiasts to find practical use for the remains of many Buicks that might otherwise just go to scrap or rot away.

As translated, this is Ariel?s Buick story.

I have owned this car since the year 1998. I was looking for a car with a long engine, and I was lucky to find a Buick. It was fairly complete, although it had been in an open field for 16 years, so the exterior was in poor shape and the wooden interior was ruined beyond repair. Then I started to look for information in order to restore it. I had no problems with the mechanics (which is my speciality) and besides it was complete, but I had problems with the wooden parts. I consulted several cabinet-makers, but the prices were too high for my budget (between U$S 8,000 and U$S 11,000 just for rebuilding the wooden structure).

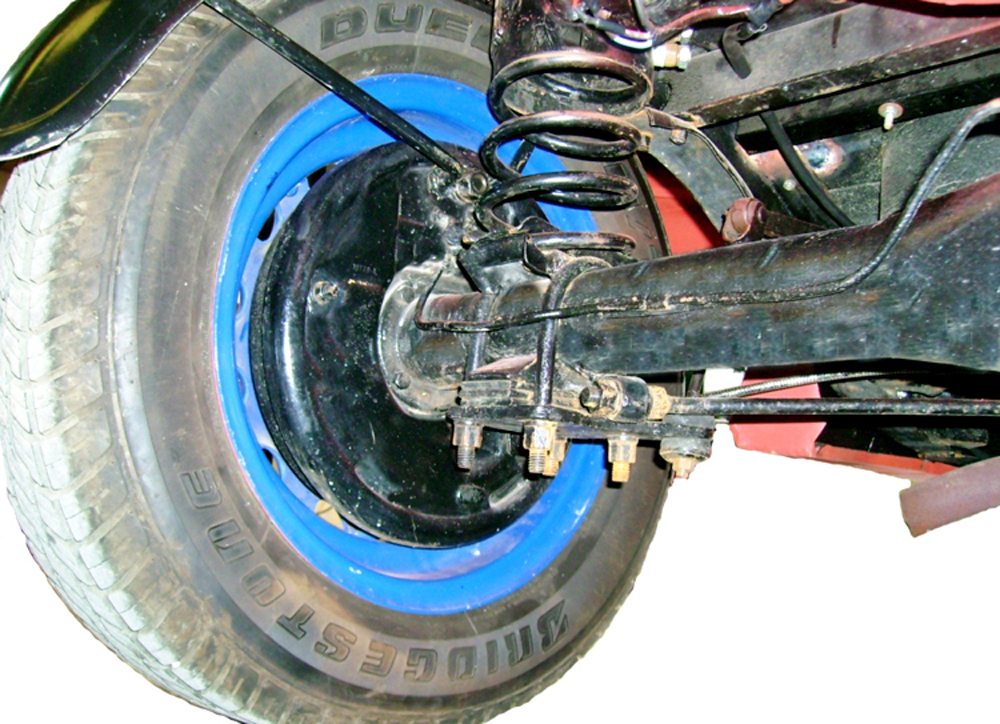

My friends insisted on doing a “Baque” (a chopped car), but I was reluctant to do it. Hot Rods are quite common, and I wanted to do something more stylish. Browsing the Web, I decided to go after a sharp front, and a driver’s seat that ends where the rear wheels start. I started by cutting 750mm from the chassis, starting from the fixing points of the rear suspension to the front. I did the same for the torsion tube and the brake lines. So I was left without a handbrake. Then I changed the position of the leaf spring supports and the rear shock absorbers, but then problems with the suspension and especially the aesthetics started to emerge. I removed the leaf springs, made a Panhard bar, cut the chasis behind the first crossbar (the one that supports the fuel tank) and I inserted a tube where I placed the suspension coil leaving the original shock absorbers (they are currently loaded with SAE 190 oil).

At that time I thought that everything was going well. I didn’t know that the problems were just starting. I made the cowling 210mm thinner and I lowered it 150mm along with the front grill. Now the original grill was useless, since it was too large. I also cut the bonnet and riveted a hinge from a bus door someone gave me, since I couldn’t find such a large hinge.

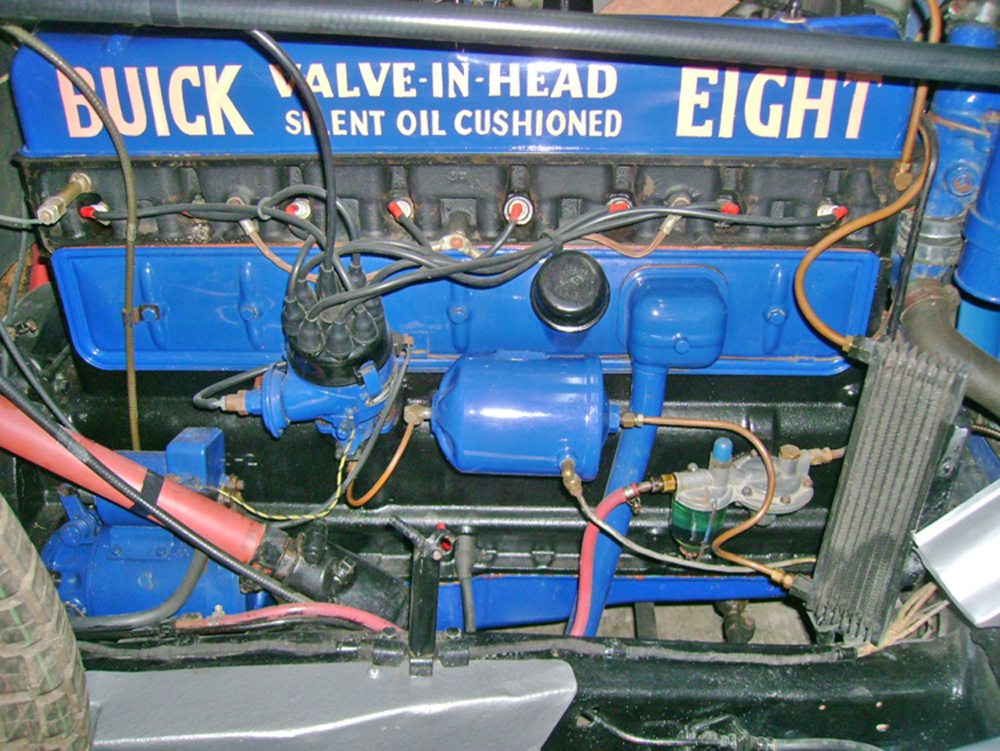

The approximate shape of the car started to show up, a seat was missing (the first one was a fruit box) and I went out for a ride, accelerating with a small cord, because the accelerator system wasn’t working since I cut the firewall. I had adjusted the main and connecting rod’s bearings and I repaired the cylinders (they are in the original measure, but when finished, I plan to rebuild it, since the cylinder number 4 makes a noise when the car is still cold). I also had the clutch repaired along with the brakes. The differential and gear box were working acceptably well with a change of oil.

Obviously, the car was not driveable, it wouldn’t go in a straight line, the steering was poor (I had also cut one and a half rings from the front spring to lower it, which caused the front wheel assembly’s geometry to change, making it difficult to steer), the rear suspension was going beyond its capacity, the pedals and steering wheel were too high, but the power and speed were incredible because of it being so light, to the point that I still don’t use the 1st gear, I start in 2nd, and it works perfectly at 100/110 km/h, with a max speed of about 130 km/h.

I wasn’t sure where to start, so I chose to lower the gear box by changing a little bit the position of the holes where it bolts to the chasis. Then heated and bent the clutch pedal in order to lower it and the same with the brake pedal. Another problem which showed up on the first test was that when I lowered the firewall, the driver’s seat position was too high, so it was solved by cutting the (just-made) floor and lowering it inside the chassis, which is where the driver’s seat is now, 100mm lowered underneath the car’s floor.

I left the new rear suspension as it was, until I assembled the whole car (gas tank, rear, shock absorbers, etc) because I wanted the car to be “sitting down” (lower on the back, which was harder than I thought, because it’s easy to lower it, but it’s hard to get the suspension to work properly).

Now I had to think how to assemble the rear end, the doors, the fuel tank, mudguards (at first I intended to leave the original ones, but after cutting the car they seemed too large), the windshield, the dashboard and instruments, the handbrake, shock absorbers (which I ultimately made by recycling the car’s rear leaf springs), the rear lights, adapted the front lights, cut the radiator (I used the car’s original, a Harrison, but I cut 150mm, which caused the car to overheat. I solved this by putting two oil radiators and a six-blade fan, I would have never used an electric fan because I like to keep everything consistent with what was available at the car’s time, bolts, etc. Even the water pump still has the rope packaging). I made the rear boat tail by adapting a 1940 Ford bonnet, which I bought for US$40, the doors have a welded tube structure and sheet metal skins, I adapted the door locks, but they are the car’s originals.

The fuel tank has a capacity of 50 litres (I used the original top) and it is hidden within the boat tail, leaving enough place to store clothing and other stuff. The grill was made with 5/16 and 1/4 bar, I bought the mudguards over the Internet and made 7/16 steel supports. They are anchored to the big nut on the brake backing plate. I assembled the instruments myself, the speedometer is the car’s original and I put it inside a round clock case, the tachometer belonged to a 1957 Ford truck and has a maximum of 4000 RPM (it was also hard to make it work because it’s mechanical and it drives from the camshaft with a part I fabricated that goes in the distribution top. The numbers in the clocks and the words “Buicks 8” were made with the “Paint” software from Windows).

The windshield belonged originally to a 1925 Chevrolet, I cut it and turned around the lower part, putting it upside down (I must still work on the frame). I redid the accelerator?s command, adapting the original parts and this works perfectly, with the original pedal and 80mm distance. I did the electrical wiring (12 volts), changed the dynamo (still keeping the 3 brush original part), the starter is the 6 volts original, but it works at 12 volts without burning out. Another problem was the height of the air filter, which was solved by making one and connecting it to the carburettor intake with a flexible rubber fabric hose. The handbrake is located in the original place, with the movements adapted and it works perfectly.

The car is painted with a two-layer paintwork (two color layers and two transparent layers), I am making the rims right now and I have to think how I am going to install the roof.

It has cost me a lot of work and money, but it pays back with satisfaction over and over again. It took time to finish, because at the same time I’m restoring together with my sons (Gonzalo and Jerinimo who always help me) and my wife Adriana (who loves cars as much as I do), a 1952 Jeep Fiat Campagnola, A 1938 Ransomes MG2 Tractor and a 1981 Honda Prelude coupe. I hope you like the car, which I love so much and it is the favourite of every exposition I go to. I am not a member of any club, because I like to drive the car every day, not just standing up looking at it in an exposition, which is what sometimes happen.

I want to thank every member of the Buick club for your interest in my “toys”, and specially John Gerdtz, who has shown interest and helped me so much with my questions.

Ariel, Jerinimo, Adriana and Gonzalo Bassanetti

More about Ariel, his work and hobby vehicle projects can be viewed at these web addresses.

Posted 05/2011