Researched and contributed by Hal Moloney from the original magazine.

New Body Mountings, pistons Increase Power, Automatic Transmission on 40

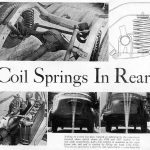

Along with a number of interesting mechanical changes including pistons which result in more power, new rubber body mountings and semi-automatic transmission optional on the Series 40, Buick has produced a leading innovation by adopting coil springs in the rear. In size and shape they resemble the front coil springs which have been used so successfully since 1934, and the theory behind these new springs has much in common with that which led to the adoption of independent front springs four years ago.

These rear coil springs, like the front, have only one job to do and that is to act as springs. They do not have to hold the axle in place with respect to the rest of the car. In a fore and aft direction this job is precisely handled by the torque tube while in a transverse direction an exact relationship between axle and frame is maintained by a cross link which is pivoted to the frame at one end and to the axle tube at the opposite end. This link is a light but stiff welded steel tube and its connections at both ends are rubber bushed. With this torque tube and cross link construction the rear axle and wheels are at all times accurately located with respect to the car just as the front wheels are precisely positioned by parallel cross arms.

Each rear coil spring rests on a bracket extending rearward from the axle tube while the top of the spring supports the frame side rail at the kickup, being insulated from it by a composition pad. A single bolt at top and bottom holds the spring securely in place.

In this spring system, friction has been reduced to a minimum and is limited to that in the rubber bushings in the cross link and in the mounting of the front end of the torque tube. By contrast, considerable friction resistance is offered by a leaf spring even when lubricated, and there is also friction of the spring bolts and bushings to be considered. While there is some difference of opinion among engineers as to how much friction, if any, should be present in the spring system, all agree that whatever degree of friction there is should be constant and should not vary with temperature and viscosity of the spring lubricant or other factors because whatever shock absorber setting is right for a certain amount of friction is wrong when the friction changes.

However with unvarying friction in the rear suspension, as in the new Buick, the original shock absorber setting should be fully effective throughout the life of the car. Hence riding quality should be unaffected by temperature and likewise should be just as good at 50,000 miles as at 1,00 and spring action should be just as limber on the first mile as after several hundred.

The comparative absence of friction naturally enhances the boulevard ride in as much as the springs are able to cushion the smallest bumps whereas conventional leaf springs do not act until the force of the bump is sufficient to overcome the static friction which binds the leaves and shackles into a solid unit.

The new construction is much simpler than the old, since two single-unit coil springs and a cross link replace two multi-leaved springs with their shackles, bolts and bushings. Buick’s torque tube construction, of course, is an essential part of this spring design as otherwise radius arms would be required to maintain the fore and aft position of the axle with respect to the frame. The coil spring design eliminates eight lubrication points as well as spring covers and spring leaf lubrication. Because of the absence of spring friction the rear shock absorbers have a diameter of 1 3/8” instead of 1” thus nearly doubling the piston area.

The cross link radius arm which exactly maintains the lateral position of the rear axle with respect to the frame is an important adjunct to the preciseness of the steering. In this connection it must be remembered that any automobile is steered by all four wheels and not the front ones alone, for certainly it is obvious that an automobile without rear wheels could not be controlled.

Buick engineers point out that leaf springs in the rear permit some lateral deflection with the result that the rear wheels may not always be where they should be and that this variation in rear wheel position naturally affects steering control. The cross link, however, eliminates the difficulty. As a consequence, it is stated that not only are the new cars more stable at high speed and in taking turns on gravelly, wet or icy roads but that, in addition, danger from a blowout is reduceHence for accurate steering, exact positioning of the rear wheels laterally by cross link, as well as fore and aft by torque tube, are of prime importance just as is the precise location of Buick front wheels by the cross arms of the independent spring suspension.

To support this contention blowout tests were made at speeds ranging from 50 to 70 mph. It is reported that there was no swerving when a rear tyre was blown and that furthermore, because of the better steering control which the new rear end design provides, maximum swerving when a front tyre was blown out was limited to 3 inches.

The steering linkage has been simplified and its action improved. A transverse drag link extends from the steering knuckle while a short rod attached to this link runs to the left knuckle. There is one less lubricating point, the steering effort curve is more symmetrical and the fact that this construction avoids the use of an intermediate steering arm eliminates this unit as a source of vibration and noise transmitted to the body by way of the frame.

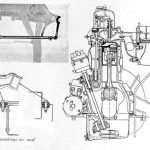

The horsepower of the Series 40 has been increased from 100 @ 3200rpm to 107 @ 3400rpm while the output of the 60, 80 and 90 has been raised from 130 @ 3400 to 141 @ 3600rpm owing to the use of a new piston with a curved or crowned head as illustrated. The greater power results principally from the fact that the new piston has permitted raising the compression of the 40 from 5.7 to 6.15 to 1 while the compression of the larger engine has been increased from 5.9 to 6.35 to 1. The piston is an aluminium alloy type with an anodised surface.

Buick has developed a new body mounting to minimise the transmission of chassis vibrations and shocks from the frame to the body. It was found that a frame vibrates and flexes most at the rear ends of the side rails. The vibration causes drumming especially in the large body panels while the flexing tends to buckle the panels and thus produce crackling noises and squeaks.

But it also noticed that there were points of negligible vibration at the middle of the rear cross member and on the side rails a few inches forward of the X member. From these neutral points the amplitude of side rail vibration gradually increases toward the rear.

At these two points the body is securely bolted to the side rails, a single thick rubber washer being used to insulate the body from the frame at these two points. The bolt at the centre of the rear cross member has a thick rubber washer under its head as well as between the body and cross member. These three bolts tie the body firmly to the frame. In addition at two intermediate points on each side rail there are large, soft rubber mountings to steady the body on the frame. These mountings consist of thick rubber washers above and below the flange on the mounting bracket. Therefore there is no metallic contact between the bolt and either the frame or the body. These soft mountings permit the frame to weave with minimum distortion of the body. There is sufficient clearance between body sills and side rails so that there is no contact between the two except as provided by the mountings just described.

Frames have been redesigned. The X member is now a channel section instead of an I-beam. Side rails are straight. The front box member is stiffer and there is a tubular cross member at the top of the kickup.

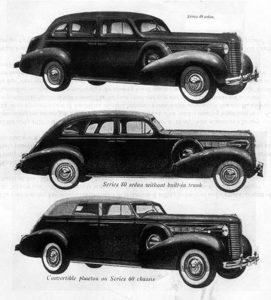

Detail changes have been made in the appearance of the new Buicks. The front line of the radiator grille is now nearly vertical and the hood is much longer. The two top panels of the hood are hinged at the centre. The hood side panels are bolted in place. They are stoutly flanged along the upper edge, therefore making radiator brace rods unnecessary. Bumper guards are taller and parking lamps on the fenders are slim replicas of the headlamps.

Wheelbases of the 80 and 90 have been increased 2 inches, the new lengths being 133 and 140 inches respectively. Series 80 bodies are 3 inches longer and 90 bodies have 2 inches more leg room. Head room has been increased 3/4 inch and doors are taller. Vertical vision through the windshield has been increased by 1 3/8 inches. The front seat is 2 inches wider and the rear seat (on the 80) is 1 1/2 inches wider.

The top of the front seat back has a soft roll construction. The instrument panels, of new design, have a recessed centre section to accommodate the radio grill. Below it are the control knobs. The position of the accelerator pedal has been changed to give the driver greater comfort and there is a ledge at its bottom for supporting the heel so that the shoe does not come in contact with the floor. The gasoline filler neck is concealed in the left rear fender. It is reached by opening a spring-closed door.

Clutch spring pressure has been increased and the throwout bearing is sealed. Clutch pedal pressure has been reduced on the 60 by the use of an over-centre pedal return spring. Various improvements have been made in the standard transmission. The clutch shaft bearing protrudes from the front about 1/8 inch and is piloted in the flywheel housing in order to obtain accurate alignment. The rear main shaft bearing is supported in a heavier and more stiffly ribbed retainer. On the 40, two-lobe synchronizers improve shifting.

A self-shifting transmission, similar to that on the Oldsmobile, is optional on the 40. Advantages include ease of operation, improved acceleration and hill climbing ability, greater fuel and oil economy, longer-lived, smoother engine operation. The clutch, which is conventional, is operated only when starting and stopping. Just under the rim of the steering wheel is a lever which may be moved to the following positions: Reverse, neutral, low-range, high-range. Low-range includes first and second with automatic shifting between them, while high-range includes first, third and fourth with automatic shifting. A start may be made in either range although low- range is recommended on an up-grade or when the engine is cold or both. The control lever may be moved from one range to the other without touching the clutch. Above 20 mph the car is in high gear unless the accelerator pedal is depressed slightly beyond its fully open position when third gear is smoothly and automatically engaged, thus providing extra acceleration and hill climbing ability exactly when it is wanted – that is, when the throttle is wide open plus.

Hypoid rear axle gearing is now used on the 80 and 90 as well as on the 50 and 60. All differential assemblies are now mounted on self-aligning roller bearings which are longer lived and which permit a greater preload. Both these advantages improve the silence of operation.

Posted 01/2004